Master batch meaning in Hindi revolves around the concept of “मास्टर बैच” (māstar baich). This term refers to a concentrated mixture of additives, pigments, or other ingredients that are added to a larger base material to impart specific properties or colors. Understanding its meaning and usage is crucial, especially in industries like plastics, polymers, and manufacturing.

Understanding the Term “Master Batch”

Master batches are essentially concentrated premixes. They provide a convenient and efficient way to incorporate additives into a base material, ensuring uniform distribution and minimizing the risk of inconsistencies. Think of it like adding a concentrated squash to water – a small amount drastically changes the final product.

Applications of Master Batches

Master batches are used extensively across various industries. In plastics, they are used to color, enhance UV resistance, add flame retardancy, and improve other properties. In the textile industry, they can be used to add dyes or special finishes. how far meaning in hindi Their versatility and ease of use make them a preferred choice for manufacturers looking to achieve specific characteristics in their final products.

Master Batch Composition and Types

Typically, a master batch consists of a carrier resin, the desired additive, and dispersing agents. The carrier resin is chosen to be compatible with the base material. Common types include color masterbatches, additive masterbatches, and combination masterbatches. Color masterbatches are used to impart specific colors, while additive masterbatches add functionalities like UV stability or flame retardancy. Combination masterbatches combine both color and additive properties in a single premix.

Advantages of Using Master Batches

There are numerous advantages to using master batches. They offer precise control over additive concentration, ensuring consistent product quality. They reduce the risk of dust and contamination, improving workplace safety. meaning of laden in hindi Furthermore, they simplify the production process, minimizing handling and processing time.

Master Batch Manufacturing Process

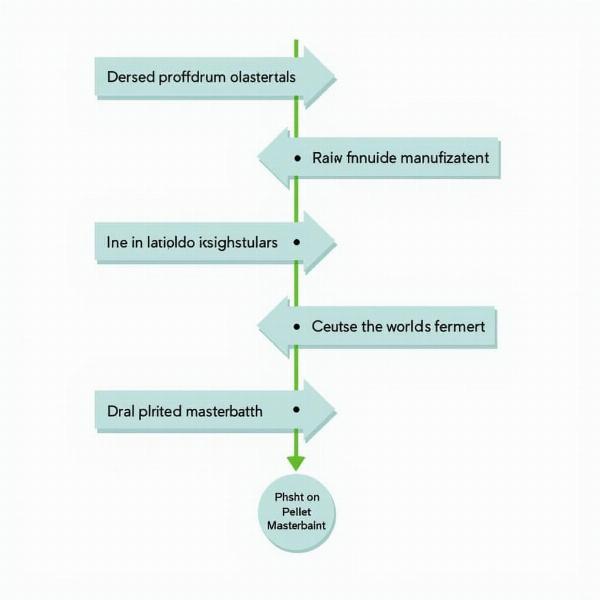

The manufacturing of master batches involves several key steps. First, the carrier resin is melted and mixed with the desired additives and dispersing agents. The mixture is then cooled and cut into pellets or other forms for easy handling and storage.  Masterbatch Manufacturing Process

Masterbatch Manufacturing Process

Choosing the Right Master Batch

Selecting the right master batch requires careful consideration of several factors, including the base material, desired properties, processing conditions, and cost. It’s crucial to choose a master batch that is compatible with the base material and provides the required performance characteristics. Consulting with a master batch supplier can be extremely helpful in making the right choice.

Common Questions about Master Batches

What is the difference between a master batch and a compound?

How do I store master batches properly?

What are the safety precautions when handling master batches?

Expert Insights

Dr. Anika Sharma, a polymer scientist, emphasizes, “Master batches offer a cost-effective and efficient way to incorporate additives into polymers, enabling manufacturers to achieve precise control over product properties.”

Mr. Rohan Verma, a manufacturing consultant, adds, “Using master batches simplifies production processes, reduces waste, and improves overall product quality.”

Conclusion

Understanding “master batch meaning in Hindi” (मास्टर बैच) is essential for anyone involved in industries that utilize additives and pigments. Master batches offer numerous advantages, including precise control, ease of use, and improved product consistency. Choosing the right master batch is crucial for optimizing product performance and achieving desired results. chime meaning in hindi

FAQs

- What is the primary function of a master batch? To provide a concentrated and consistent way to add additives and pigments to a base material.

- Why are master batches preferred over adding raw additives directly? They offer better control, reduce contamination, and simplify the production process.

- What industries commonly use master batches? Plastics, polymers, textiles, and other manufacturing industries.

- What are the key components of a master batch? A carrier resin, the desired additive, and dispersing agents.

- How are master batches typically supplied? In pellet or granular form for easy handling and incorporation.

- What factors influence the selection of a master batch? Base material compatibility, desired properties, processing conditions, and cost.

- Where can I find more information on master batches? Consult with specialized master batch suppliers or industry publications.

Meaning-Hindi.in is your one-stop solution for all your Hindi translation needs. We offer a comprehensive range of translation services, including business and commercial document translation, certified and legal document translation, technical and user manual translation, website and localization translation, and academic translation. Our expertise covers a variety of specialized fields, ensuring accurate and culturally sensitive translations. Contact us today at [email protected] or +91 11-4502-7584 to discuss your translation requirements. Meaning-Hindi.in helps bridge the language gap for businesses and individuals alike.